The challenge to create a flawless surface of the Bel Canto’s platine has been overcome with innovation, hard work and an awful lot of brushing

So, imagine it’s you who’s making a brand-new watch. Specifically, you’re keen to uncover a manufacturing process that will guarantee the most perfect possible finish for its most prominent surfaces. You might look at hammering or stippling, bead blasting or a high polish – each common solutions in jewellery design. But chances are you’d keep coming back to the idea of sunburst brushing. Little else can compete with its striking, pleasing, endlessly intriguing end result, which catches the light in glorious ways, and – when examined under even the most powerful of loupes – is revealed to be utterly without flaws.

Once the platine itself has been manufactured to the most exacting of specifications it is then passed to a specialist dial factory, where the surface will go through a number of additional processes.

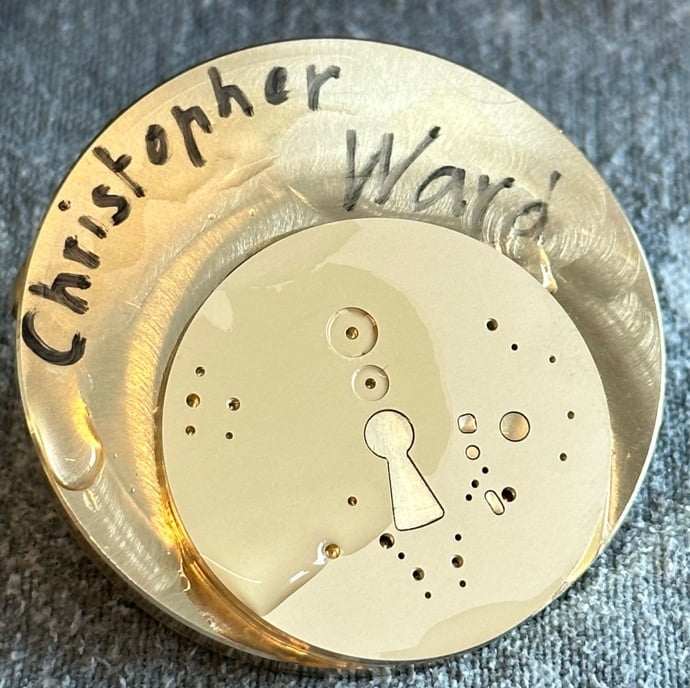

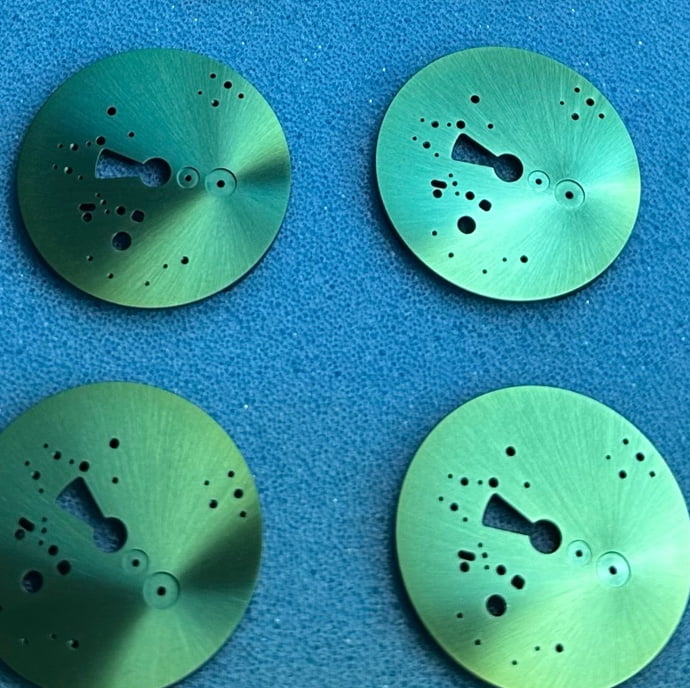

First, it will be polished smooth, by rubbing it with pumice-stone. Next comes a silver plating. Then our supplier carefully places the blank in a specially designed holder and brushes the surface using a state-of-the-art machine, which uses brushes made of brass. This allows for a precise and even effect, ensuring that the surface is entirely uniform in appearance.

After brushing, the blank is washed using a specially formulated cleaning liquid, to remove any residues. Once dried, a rigorous quality control process is conducted to ensure that your specific platine meets our highest standards of excellence.

Producing a regular dial in this fashion is difficult enough, but remember, we’re talking about a platine here – which does further jobs, and so contains numerous further challenges. Instead of the limited number of openings that most dials suffer – often just one for the hands at the centre, perhaps joined by a date window – your Bel Canto’s platine actually has 30 openings, as so much of the mechanical movement has to be directly mounted to it, both the glamorous elements visible above the coloured surface, and all the rest working invisibly below.

“Producing a flawless surface with so many openings can be really challenging,” says Frank Stelzer, Technical Director at Christopher Ward’s Biel atelier, “but our skilled suppliers have the know-how and dexterity to achieve it every time. Part of what makes this possible is the use of silver to guarantee a pristine surface.”

Oh, but there’s more. Another crucial part of Bel Canto’s design, and one that makes things more complicated yet, is that the sunray effect doesn’t radiate from the centre of the circular platine in the usual fashion, but instead from a spot roughly halfway between the centre and the 12 o’clock position. Why? So that it appears to shine from the very middle of the time-telling sub-dial that occupies the top portion of the watch, of course. To achieve this, the brushing will have to apply a different length of rays to the entire 360 degrees, which introduces a new difficulty: you need to find a way to make sure exactly the same pressure of brush-stoke is applied to both the long and short sunrays.

After this, there’s one final stage, as rhodium plating is applied to the surface as a necessary ‘base coat’ for the colouring, which is applied through a highly technical ionic vacuum treatment.

And the end result? A truly stunning combination of rich colour and an ever-changing play of light that becomes mesmerising at certain angles. Though each finished Bel Canto platine is as gorgeous as the next, it’s simultaneously unique too, its polishing ever-so-subtly different to those of its siblings. It means your Bel Canto truly is one of a kind.

For more behind the scenes stories from Christopher Ward visit; christopherward.com/loupe

Related watches

Sign up to Loupe magazine

Loupe is Christopher Ward’s quarterly in-house magazine. If you want to know what’s happening at CW (and you love great journalism), this is where to start. Alternatively, you can read all our back issues on your computer, tablet or phone.

Order your free copyRead Loupe online