Industrial evolution

Industrial evolution

An Englishman in New York (well, two actually, oh, and a Swiss)– words by Mike France, CEO & co-founder.

It’s a good while since I used to pen every word about CW – thank goodness I hear many of you cheer - but The Twelve X (Ti) is such an extraordinary watch, created to celebrate the twin anniversaries of our founding in 2004 and the ten years since we introduced our own movement onto an unsuspecting watch world in 2014, that I felt compelled to tell you, in my own words, how it came to life.

And, like so many of our watches, the story of this 41mm diameter titanium version of The Twelve owes its creation more to impassioned conversation than any masterpiece of market positioning: on this occasion the lively conversation was between Will Brackfield, our senior designer, Jorg Bader Jnr, head of product development and me as we wandered through midtown New York on our way to visit the WatchTime show in New York on a drizzly Sunday morning. The first ‘X’ prototype, which we had recently been reviewing, was a joy to behold: the most extensive open-heart surgery of our 5 day chronometer movement had achieved a view, front and back, that took our collective breaths away. But on that walk to Gotham Hall on Broadway, we wondered aloud whether by pushing the aesthetic boundaries further by reconsidering finish of the bridges and by using two grades of titanium on the case, we could elevate it to an even higher plane, and make it even more special.

Several iterations later, the team had not only achieved this, but had also worked tirelessly with our magnificent manufacturing partners to achieve levels of machine-finished polishing on the platine and bridges that signals another leap forward in our ability to make haute-horologie more accessible than ever. Innovation comes in many guises, and by encouraging incredibly skilful programming of the most advanced CNC machines around, we have developed an approach to diamond-cut machining the facets of the train, automatic and balance bridges that delivers a finish almost indistinguishable from the most skilled hand-finished results. You might even say that the desired industrial-chic look of The Twelve X (Ti) is, somewhat appropriately, born of our own Industrial Evolution - as well as an inspiring walk on a grey Manhattan morning!

Calibre SH21

Calibre SH21

The calibre SH21 consists of 100 raw parts, totalling 198 when considering both raw and newly crafted components. What sets us apart is our in-house manufacturing of critical components like the platine, train bridge, automatic bridge, hour bridge, and balance bridge

Beauty and the bridges

The multi-layered, multi-angled bridgework which supports the movement is only possible through the use of the Elara NS CNC milling machine, which uses a diamond cutter to achieve incredible accuracy. The work was undertaken by Paoluzzo, a maker of precision medical, aviation and horological parts.

Crystal clear

Thanks to the domed sapphire crystals at both ends of the watch, you can view every part of SH21: from the twin barrels that deliver the famous five-day power reserve to the winding mechanism at 3 o’clock. The slim Super-LumiNova®-filled rhodium minute ring allows you to see more of the barrels and – another first – the escapement.

Globolight© and rhodium dial ring

The dial is framed by a rhodium ring round the outside, with an applied luminous Globolight© wedge at 12 o’clock.

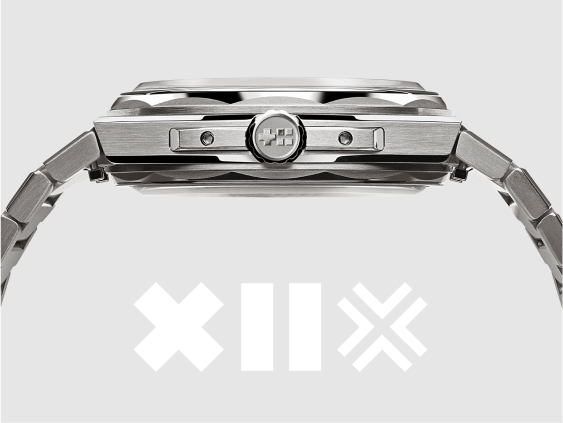

Taking titanium further

Grade 5 titanium – an alloy of titanium, aluminium and vanadium – is found on the bezel and case back. The material – which is harder than its Grade 2 counterpart – allows for improved mirror polishing, and offers a greater contrast to the satin-brushed finish of the rest of the case. A key design detail.

A smooth, adjustable bracelet

The Twelve X (Ti)’s bracelet is built from single links to deliver a taper that goes from 25mm to 17mm, while the satinised finish comes courtesy of a water-grinding process. The bracelet closes with a butterfly clasp – fitted with a micro-adjustment mechanism for the first time in The Twelve series. This allows the wearer to adjust the length by up to 1.5mm per side – and 3mm in total.